There can be several reasons for frequent thread breaks on a Tajima embroidery machine. Some common causes include:

-

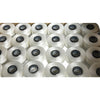

Poor thread quality: Using low-quality thread can lead to frequent breaks and cause other issues, such as tangling and fraying.

-

Incorrect needle size: If the needle size is not appropriate for the type of thread and fabric being used, it can cause excessive friction and lead to thread breakage.

-

Loose thread tension: If the tension on the thread spools is too loose, it can cause the thread to break more easily during the embroidery process.

-

Dirty or worn needle plate: If the needle plate is dirty or worn, it can cause the needle to move unevenly, leading to thread breakage.

-

Dull needle: A dull needle can cause the thread to break due to increased friction. Regularly checking and replacing worn needles can prevent this problem.

-

Incorrect hooping technique: Incorrect hooping can cause the fabric to stretch or shift during stitching, leading to thread breakage.

-

Excessive speed: Running the machine at too high a speed can cause the thread to break due to increased tension.

By addressing these potential issues and maintaining your Tajima machine, you can reduce the number of thread breaks and ensure smooth and consistent embroidery.

Here are some steps you can take to prevent thread breaks when operating an embroidery machine:

-

Use high-quality thread: Use high-quality thread that is specifically designed for embroidery. Low-quality thread is more prone to breaking and can cause other issues, such as tangling and fraying.

-

Choose the correct needle size: Select the appropriate needle size for the type of thread and fabric being used. A needle that is too small can cause excessive friction and lead to thread breakage, while a needle that is too large can damage the fabric.

-

Adjust thread tension: Regularly check and adjust the tension on the thread spools to ensure it is not too loose or too tight. Incorrect thread tension can cause thread breakage.

-

Clean the needle plate and hook: Regular cleaning of the needle plate and hook can prevent thread breakage by reducing friction between the needle and the machine components.

-

Use a sharp needle: Regularly check and replace dull needles, as a dull needle can cause the thread to break due to increased friction.

-

Hoop the fabric properly: Proper hooping is essential for preventing thread breaks. Ensure the fabric is stretched evenly in the hoop and is not too loose or too tight.

-

Slow down the machine speed: If you experience frequent thread breaks, try reducing the machine speed. Running the machine at too high a speed can cause increased tension, leading to thread breakage.

By following these steps, you can reduce the number of thread breaks and ensure a smooth and consistent embroidery process.